Continuous Carbonization Furnaces

Product Introduction

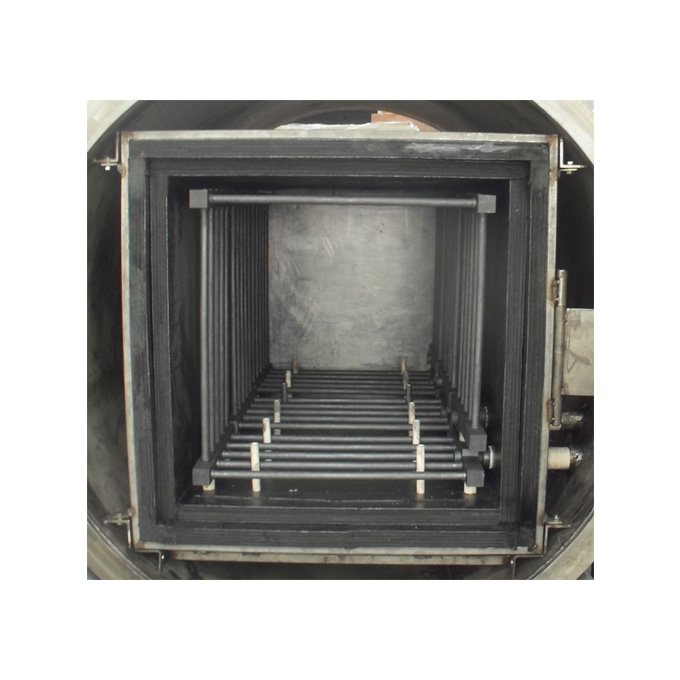

CX-CCF series are continuous furnaces with resistance heating method. These furnaces are specially designed for carbon fiber production.

Application

Cxinduction’s capabilities extend from thermal equipment designs for a specific unit operation through fully integrated production lines producing carbon fiber, carbon nanotubes, and metal oxides.Fully Integrated Control Systems.

General Features

· Furnace designed especially for high temperature carbonization of carbon fiber. All key special requirements for this process take into account in design of these series.

· Easy installation and maintenance.

· Muffle made of high density graphite in order to have in-direct radiation heating for better temperature uniformity and as well as waste gas management.

· 9 - 12 heating zones, of which 6 - 9 heating zones are controllable within the range of 500-1600°C. The other heating zones are used for cooling steps.

· The furnace mouth can be segmented

· The temperature gradient and uniformity is guaranteed for proper setting of processing materials, which make sure there is no material shrinkage or expansion problems.

· High density graphite heating elements are uniformly distributed to ensure temperature uniformity in the hot zone. Heating elements powered by direct current (DC) switch mode power supply with low voltage (<50V) which increase heating element life in comparison to use of AC transformers. The power of the hot zone is regulated through the phase shift thyristors.

· High quality rigid graphite felt as the insulation of the hot zone.

· Delicate measurement system for oxygen content in protective gas and dew point tracking.

· Gas flow control system.

· Over-temperature, over-pressure, gas status, water lack and power failure alarms and automatic mechanical interlock for over-pressure protection.

· All the running parameters are stored in the PLC system. All stored parameters can be transferred into your personal computer through a USB port.

· High precision smart temperature controller which can store 20 programs with total 400 segments.

· Fully automatic PLC monitoring system.

· Remote operation, failure diagnosis and software upgrading.

· Multi zones design for higher temperature uniformity.

Optional Features

· Gas Purification System

· Closed Loop Cooling Water System

· Distributed Control System (DCS)

· Multi chambers (with only one control cabinet for all chambers)

· Tail gas treatment system

Technical Details of Horizontal Models (Cubic Hot Zone)

|

Model |

CX-CCF40/120 |

CX-CCF50/150 |

CX-CCF60/180 |

CX-CCF60/200 |

|

Max Working Temperature |

1600°C |

|||

|

Usable Space (mm) W×H(customized)×L |

400×200×1200 |

500×200×1500 |

600×200×1800 |

600×200×2000 |

|

Number of Heating Zones(customized) |

3 |

3 |

3 |

3 |

|

Temperature Uniformity (ΔT between 1000°C and 2200°C) |

±10°C |

|||

|

Max. Heat-up Rate (CEDRT)* |

15°C/min |

|||

|

Heating Power |

75 KW |

90 KW |

120 KW |

160 KW |

|

Working Atmosphere |

Inert Gas (Ar or N2) |

|||

|

Supply Voltage |

3P, 380V, 50Hz/60Hz |

|||

|

Cooling Water Pressure |

1.5~2.5 bar |

|||

|

Cooling Water Temperature |

≤28°C |

|||

* CEDRT: Clean, Empty, Dry, Room Temperature Furnace